DOSING INSTALLATIONS FOR LIQUIDS:

- Choline chloride

- Methionine

- Lysine

- Water and acidifiers

- Molasses

- Glicerine

- Aromatic substances

- Formadehyde

- Winiasa

- Lecifeed

Installation consists of the following devices:

- Heater with filters and pump unit

- Scales tank suspended on strain gauge or mass flow meter

- Heated and insulated pipeline of acid-resistant steel

- Valve unit

- Interceptor with spray nozzles unit and blow-off system

- Control cabinet

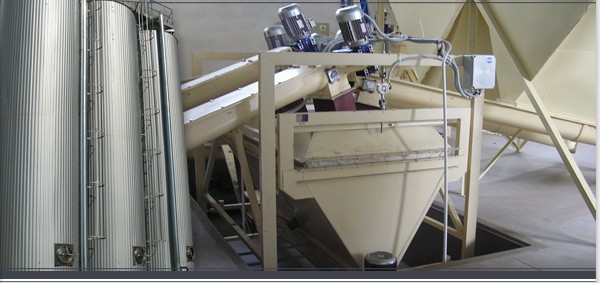

INSTALLATIONS FOR MELTING AND DOSING FATS

- Heated and insulated tank made of acid-resistant steel with a capacity of 1200 - 2000 litres to melt fat

- Installation for dosing fat

INSTALLATIONS DOSING FATS AND ENZYMES FOR COLD PELLETS

- Greasing 0.5-6%

- Full automation of the dosing process

- Accuracy of liquid dosing 0.2%

- Accuracy of flow scales 2%

DEVICES

Buffer tank with electro-pneumatic bolt and pellets level sensor.

Flow scales for constant pellets weighing.

Devices for lubrication – greasing chamber with nozzles or a device with rotating plates.

Enzymes dosing – special pneumatic nozzles.

Mixing devices – mixing screw conveyor or two-shaft paddle mixer.

Installations for dosing liquids, dosing pumps adjusted to be steered by inverters.

And additionally devices for transporting pellets: bucket elevators, chain and belt conveyors.